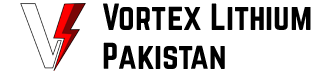

Is your trusty cordless drill gathering dust because its battery just won’t hold a charge? Don’t toss it out just yet! At Vortex Lithium PK, we believe in maximizing the lifespan of your tools and empowering you with the knowledge to do so. That’s why we’re sharing our comprehensive 5-step guide to repairing your cordless drill battery pack. This isn’t just about fixing a battery; it’s about extending the life of your valuable tools, saving money, and contributing to a more sustainable future.

Why Repair Instead of Replace?

Modern cordless drills, especially high-performance models like those from Vortex Lithium PK, are built to last. Often, the first component to show signs of wear is the battery pack. Replacing an entire battery can be costly, and in many cases, only a few individual cells within the pack are failing. By learning how to repair your battery, you can:

-

Save Money: Individual cell replacement is significantly cheaper than buying a whole new battery pack.

-

Reduce Waste: Keep batteries out of landfills and contribute to a greener planet.

-

Extend Tool Lifespan: Get more years of reliable service from your favorite cordless drill.

-

Gain Valuable Skills: Understand the inner workings of your tools and become more self-sufficient.

Your Essential Guide: 5 Steps to a Revitalized Battery Pack

Before you begin, gather your tools: a multimeter, an IR tester (internal resistance), a spot welder (or soldering iron for specific situations), and replacement lithium-ion cells (ensure they match the specifications of your original pack).

Step 1: Cell Charging – The Foundation of Performance

The first step in diagnosing and repairing your battery pack is to individually charge each cell. This allows you to assess their ability to hold a charge and identify any cells that are completely dead or deeply discharged. Use a smart charger that can monitor individual cell voltage and current. Fully charging each cell ensures you start with a level playing field for subsequent tests.

Step 2: Capacity Testing – Unveiling the True Power

Once charged, the next crucial step is to test the capacity of each individual cell. A dedicated capacity tester will discharge the cell at a controlled rate and measure the total milliampere-hours (mAh) it can deliver. This step is critical for identifying weak cells that may hold a charge but quickly lose power under load. Cells with significantly lower capacity than the others are prime candidates for replacement.

Step 3: IR Testing (Internal Resistance) – The Health Indicator

Internal resistance (IR) is a key indicator of a battery cell’s health and its ability to deliver current efficiently. A high internal resistance means the cell struggles to release power, leading to heat generation and premature voltage sag under load. Using an IR tester, measure the internal resistance of each cell. Cells with significantly higher IR values compared to new cells or healthy cells in your pack should be replaced to ensure optimal performance and longevity of the entire pack.

Step 4: Spot Welding – The Professional Connection

For robust and reliable connections within your battery pack, spot welding is the preferred method. Spot welding creates strong, low-resistance connections between the nickel strips and the battery terminals, crucial for efficient power transfer and minimal heat generation. If you’re replacing individual cells, you’ll need a spot welder to reassemble the pack securely. Ensure you have proper safety gear and practice on scrap materials first.

Step 5: Soldering – When Precision is Key

While spot welding is ideal for main pack assembly, there might be instances where soldering is necessary. This could include connecting the battery management system (BMS) wires, thermal sensors, or making other delicate connections that require more precision than spot welding. When soldering, use a low-wattage iron, flux, and good quality solder to avoid overheating the cells and ensure strong, clean joints.

Vortex Lithium PK: Powering Your Projects, Sustainably.

By following these steps, you can confidently repair your cordless drill battery pack, saving money and extending the life of your valuable tools. At Vortex Lithium PK, we’re committed to providing high-quality tools and empowering our community with the knowledge to maintain them. Explore our range of drills and lithium-ion battery solutions designed for durability, performance, and sustainability.

Ready to get started? Watch our detailed video guide on cordless drill battery repair!